Specialist Storage Tank Welding Inspection Providers for Precision and Safety Guarantee

Expert tank welding evaluation services play an important function in making certain that these essential components are met with steady persistance. As we delve into the world of professional storage tank welding evaluation services, the elaborate procedure of securing both accuracy and security unravels, dropping light on the vital nature of this specific proficiency.

Importance of Specialist Tank Welding Assessments

Guaranteeing the architectural stability of commercial tanks through professional welding inspections is important for maintaining functional safety and security and regulative conformity. Professional tank welding examinations play a basic function in determining prospective issues, such as splits, leakages, or weak joints, that could endanger the functionality and safety and security of the tank. In general, expert container welding assessments not just improve functional security however likewise contribute to the durability and efficiency of commercial tanks, making them a critical aspect of commercial upkeep methods.

Certifications of Tank Welding Inspectors

Professional storage tank welding examinations play a pivotal function in promoting the architectural integrity of industrial storage tanks, requiring certified tank welding examiners with details credentials and know-how. A basic qualification for tank welding inspectors is certification from recognized bodies such as the American Welding Society (AWS) or the International Institute of Welding (IIW) In addition, examiners need to have relevant instructional histories in areas like welding design or metallurgy to realize the technical elements of storage tank welding thoroughly.

Key Benefits of Expert Assessments

Specialist inspections performed by certified tank welding examiners offer indispensable benefits to commercial container operators and stakeholders. Professional examinations assist in making certain the architectural stability and security of the tanks.

Furthermore, regular examinations contribute to extending the life-span of the tanks, maximizing the return on financial investment for industrial container operators. Eventually, the vital benefits of expert examinations include governing conformity, safety assurance, operational efficiency, and cost-effectiveness, making them vital for maintaining high criteria in tank welding methods.

Market Specifications Conformity in Inspections

Assessors play an essential role in guaranteeing that storage tank welding methods straighten with well-known sector requirements and laws, specifically in the world of compliance throughout evaluations. Welding evaluations are carried out to verify that the welding work fulfills the needs established forth by organizations such as the American Welding Culture (AWS), American Society of Mechanical Check Out Your URL Engineers (ASME), and the Occupational Safety And Security and Health And Wellness Administration (OSHA)

Ensuring Security and Precision in Welding

Safety and security and accuracy are critical considerations in the realm of welding methods for making certain the stability and top quality of container structures. Welding procedures need to comply with stringent safety methods to stop accidents and ensure the health of personnel associated with the welding operation. Precaution such as correct air flow, safety gear, and comprehensive risk analyses are crucial in keeping a website here safe and secure functioning atmosphere. In addition, accuracy in welding is necessary for the structural integrity of containers, as any type of errors or defects in the welding process can jeopardize the stamina and toughness of the storage tank. Ensuring specific welding methods, such as keeping the appropriate temperature and welding criteria, using top notch materials, and performing complete evaluations, is vital to guarantee the durability and reliability of the container structure. By focusing on security and accuracy in welding methods, firms can maintain the highest possible standards of high quality and workmanship in the construction of container structures, ultimately boosting operational safety and security and efficiency.

Final Thought

To conclude, expert tank welding evaluations play a vital role in guaranteeing safety, accuracy, and conformity with market criteria. By relying upon certified examiners to assess welds, firms can reduce dangers and stop prospective dangers. Expert evaluations use various benefits, including boosted quality assurance and satisfaction for stakeholders. It is imperative for companies to focus on precise and comprehensive assessments to support the honesty of their container welding procedures.

Specialist tank welding assessments play an essential role in promoting the structural honesty of industrial storage tanks, necessitating certified tank welding examiners with specific qualifications and knowledge. A basic certification for container welding inspectors is qualification from acknowledged bodies such as the American Welding Culture (AWS) or the International Institute of Welding (IIW) Welding evaluations are performed to verify that the welding job fulfills the demands established forth by organizations such as the American Welding Society (AWS), American Culture of Mechanical Designers (ASME), and the Occupational Safety And Security and Health Administration (OSHA) In addition, accuracy in welding is necessary for the architectural integrity of storage tanks, as any type of mistakes or problems in Get More Info the welding procedure can compromise the strength and sturdiness of the storage tank. Making sure accurate welding strategies, such as keeping the correct temperature level and welding specifications, using premium materials, and carrying out complete inspections, is vital to guarantee the longevity and reliability of the storage tank framework.

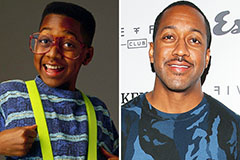

Jaleel White Then & Now!

Jaleel White Then & Now! Ariana Richards Then & Now!

Ariana Richards Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!